The large-scale production of renewable fuels depends on a reliable energy and water supply - especially in regions with water stress. A key technological hurdle is the scaling of electrolysis, which must be suitable for industrial use, economically efficient and robust. The supply of CO₂ is also complex: it can be provided via point sources or direct air capture (DAC), which presents different challenges. At the same time, setting up the infrastructure for hydrogen transportation, CO₂ handling and storage is crucial to ensure a smooth production process. In addition, the dependencies between the individual process stages are a critical factor: fluctuations at one point have a direct impact on the entire system.

How the innovation focus works

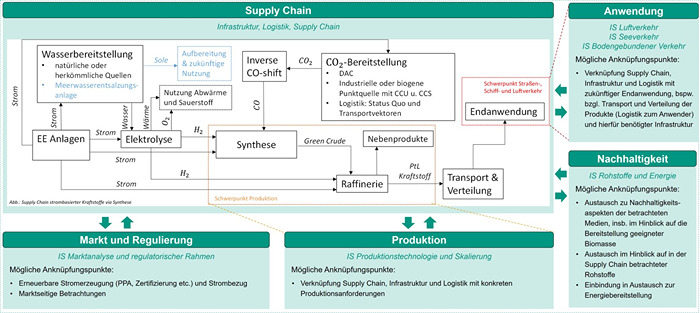

The field of activity of the focus area Supply Chain covers all processes of raw material and material processing: starting with the provision of the various starting media, through electricity generation and the provision/preparation of water for electrolysis, via the electrolysis process itself to the provision of the prepared hydrogen and carbon for the subsequent synthesis process. The work of the Supply Chain innovation focus area therefore already starts at these stages.

The overarching aim is to create transparency about the upstream processes - i.e. to clearly show which steps, dependencies and resources are necessary for the production of renewable fuels - and to demonstrate the conditions under which this production can be scaled up.

Experts from the Center for Solar Energy and Hydrogen Research, Infraserv Höchst and the state agency e-mobil BW are responsible for the innovation focus.

%20KIT_Markus%20Breig%20und%20Amadeus%20Bramsie-3.jpg)